In 2003, a new company appeared in the Georgian business sector aiming to achieve unconditional trust and become a leading player in the construction industry. Forbes Georgia spoke to Levan Jankarashvili, Executive Director of construction material manufacturing and importing firm GRC, about the company’s 20-year history.

Let us start from the beginning. How was GRC founded, and what results has the company achieved in its 20 years of existence?

We celebrate two decades of transformational development in the Georgian construction sector in December. GRC quickly turned from a newcomer to a leading industry player. I believe we represent the best example of strategic expansion, innovation and sustainability in the sector.

The company started out in 2003 as a minor importer of roofing and waterproofing materials. Within 20 years, we have established ourselves as a stable and solvent company that employs around 400 people. Apart from imports, we also produce certain construction materials and are one of the leading suppliers in this sector.

From 2006 to 2008, I was the company’s CFO. I rejoined GRC as Executive Director 13 years later and found a completely different company in terms of size and ambition. I can confidently say that we are fulfilling our brand promise – we have everything needed for construction.

What has facilitated GRC’s growth?

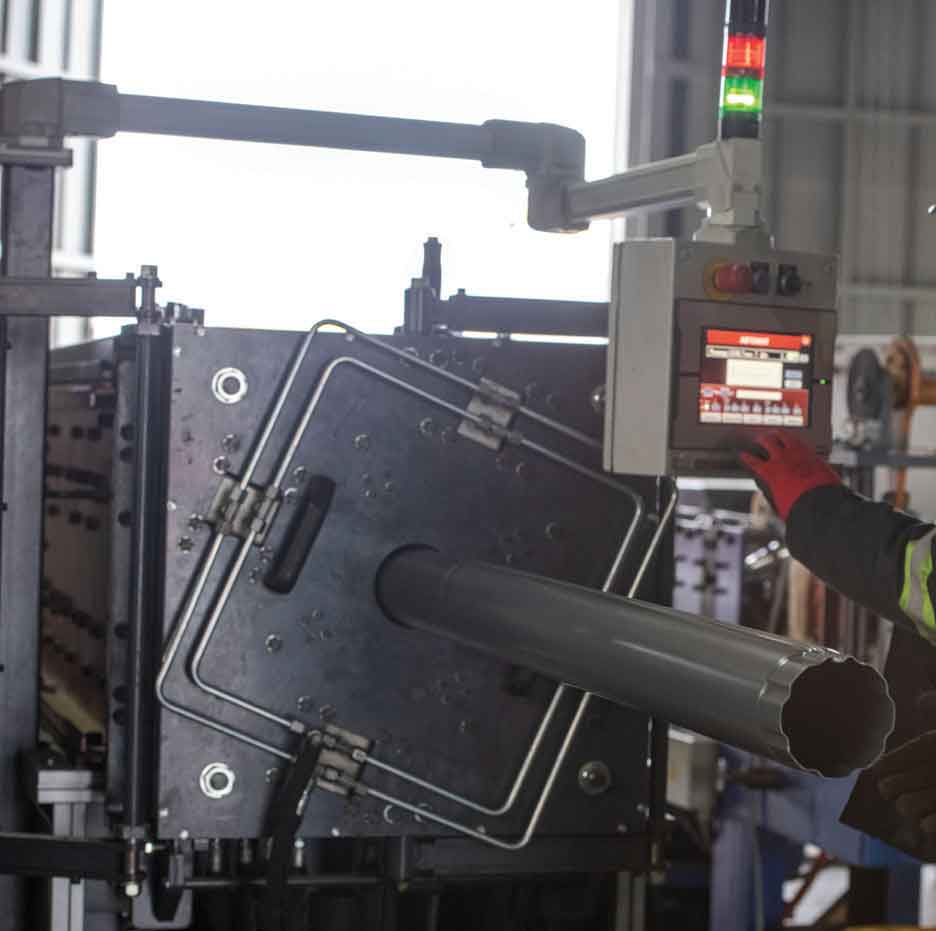

In 2006, the company expanded into the construction chemicals business and became the exclusive partner of BASF in Georgia. We are currently partnering with the Sika brand. In 2009, the company acquired Finnish metal-ceramic equipment and started producing roofing materials, thereby expanding its portfolio and changing the quality and standards of manufacturing in Georgia. Part of the expansion was the purchase of a profiled phenyl plant and the production of Profnastil roofing. Your readers may find the importance of these measures surprising, but industry players will agree that these were innovative and timely decisions for our sector at the time.

Since 2012, GRC has also been expanding geographically. Our first regional branch opened in Batumi. A few years later, we also opened a multifunctional branch in Kutaisi.

Parallel to geographic expansion, our team has also been actively working on increasing production. The GRC roofing plant on Peikrebi Street in Tbilisi was built in 2013. A year later, gypsum cardboard was added to our production line. With government support, we opened another new plant in Rustavi in 2015, where we produce fireproof rock wool sandwich panels. GRC was the first company to manufacture structural iron in the South Caucasus in 2019. Even during the pandemic, we launched the production of premium-range RainLine gutter systems made of double-sided painted tin.

I am sure you would agree that achieving these results quickly requires a clear strategic vision and the support of a dedicated team. I am confident that the future of GRC will boast even more significant achievements in our third decade of existence.

How do you position yourself on the market today?

Today, GRC stands out in the Georgian construction market in several important aspects. First and foremost among them is innovation and our focus on quality. We have a solid reputation in our industry in this regard. The choice we offer regarding the range of products for different market segments is equally important.

International strategic partnerships have a positive effect on our reputation. GRC officially represents global brands such as Sika, Samsung, Dongbu, SSAB and others in Georgia.

At the same time, the experience accumulated over 20 years helps us adapt to sustainability trends – be it energy efficiency, eco-friendliness, or other aspects.

It is not an exaggeration to say that the customers themselves are the most noteworthy influence on the positioning of GRC. We are proud to have many devoted clients who have remained loyal to GRC’s product diversity, innovation, strategic partnerships, sustainability, and quality for 20 years.

Your company has been producing building materials for 14 years. What is the split between imports and local production?

This year, the sales ratio between locally produced and imported products has been almost equal. It is important to note that GRC is one of the largest traders of rebar manufactured by GeoSteel in Georgia. Therefore, products manufactured in Georgia account for the largest share of our sales.

What does your portfolio look like today?

Our client portfolio is divided into corporate, infrastructure, wholesale, and retail segments. GRC’s portfolio includes thousands of clients and representatives of both international and local companies.

As far as our production and sales activities are concerned, the availability of our products and the production line itself have both been significantly expanded. GRC has warehouses and showrooms in several regions, where retail and wholesale customers will find more than 4,000 different items from 11 categories. Our commercial team serves corporate and infrastructure clients.

We must emphasize the significant investment that GRC has made in the intellectual development of the company and the industry as a whole. The company has made important local decisions and created guidelines since the 2000s. We have constantly brought new knowledge and the best international practices to the country. We still use the same approaches today: with the direct involvement of business development and commercial managers, innovative and sustainable approaches are being localized, and guidelines and the relevant Georgian terminology are being developed.

Our diverse portfolio is based on the combination of all these factors.

Parallel to continuous development, your company had to operate against the background of several significant crises. What were the main challenges, and how did you tackle them?

The company’s success in the construction sector largely depends on macroeconomic stability. We have been through several major crises, including the global financial crisis of 2008, the COVID-19 pandemic, the 2008 war in Georgia, and the ongoing war in our region. All these factors have a critical impact on business stability.

It is crucial that GRC has overcome all these challenges while fully delivering on the promises made to employees, customers and suppliers.

Our main goal is the growth and development of the company, although external factors correlate with achieving our goals. It should be noted that our activities are pretty capital-intensive.

At this stage, we expect that the stable growth of our economy will continue. Positive expectations are supported by data, such as the increased number of construction permits or the figures for imported and manufactured goods, which indicate an increase in our market share.

As for the company itself, GRC is relatively stable in terms of liquidity. The company’s accumulated retained earnings fund a sizable portion of our capital structure. We can also acquire various financial resources, if necessary, be it from local or international banks. Our financial results mean we are an extremely attractive partner for investors and financial institutions.

How many employees does GRC currently have?

We currently have around 400 professional staff, of whom 220 work in operations, 100 in commerce, 60 in administration and approximately 20 in logistics. Additionally, we work with thousands of individual contractors and outsource work to companies of various sizes and sectors.

The company’s team consists of professionals with a distinguished formal education and decades of practical experience. It is this synthesis that creates GRC’s competitive advantage in operational activities.

How would you characterize your management style?

I would start by emphasizing that my preferred management style is greatly influenced by the company’s philosophy and values. Since its foundation, GRC has taken a long-term view of human capital development. Therefore, transformational leadership is the most critical aspect of the company’s management.

GRC encourages leadership and teamwork. We put a lot of resources into staff training programs to share best practices and promote innovation within the team. Our team members’ expertise in various areas of the construction industry is also essential.

The presence of employees with such a comprehensive vision and internationally certified knowledge makes us a company that is trusted to implement the country’s iconic infrastructure projects.

As for my role as CEO, I would say that my primary task is to provide the team with a clear long-term vision for the company’s growth that focuses on sustainability and strategic expansion. My goal is for my team to feel that their contribution and role in the company’s development are being valued.

It will be important to cope with the demands of a constantly and rapidly changing market and to retain and enhance the trust and satisfaction of our customers by maintaining high standards of products and services.

I firmly believe that, together with the GRC team, I can complete all these tasks successfully.

How does GRC ensure quality?

Quality control at GRC includes two areas: quality control of production and warehousing and providing customers with quality products. In the case of the former, we at GRC are guided by the concept of total quality control, where each stage of the operational process is identified, and each aspect of quality compliance of our manufactured or imported products is fully covered. Regarding the latter, we use a unique methodology to evaluate client satisfaction continuously. We also periodically hire consulting firms to aid us in the aforementioned processes.

As for the quality assurance goals themselves, our main objective is to fully comply with the existing standards and regulations in the construction materials industry. Activities undertaken for this purpose include regular testing of products against specifications, permanent evaluation of materials by suppliers, detailed documentation of quality tests and corrective actions.

At the same time, we seek to obtain the relevant certificates. Our production lines undergo regular audits to confirm quality compliance. These approaches ensure the high standards of GRC’s construction materials and services.

What are your company’s plans for the coming years, and what are your targets?

The focus in the coming years will be on the expansion of production and product lines. Our strategic objective is to be the region’s leading supplier of advanced and sustainable building materials. To this end, we must introduce the latest manufacturing technologies at GRC. The company’s digital transformation will also be an important aspect of our action plan.

Our ambition is to expand geographically further – that is, both in Georgia and internationally. Therefore, the emphasis will be on developing and strengthening domestic and international partnerships.

As for the long-term perspective, we want to get as close as possible to EU standards and requirements to ensure that the company is ready to benefit from the prospects that Georgia’s EU candidate status will bring.

S