- The Bandag plant will be built in Rustavi, representing a $2 million investment.

A landmark agreement between Tegeta Motors and Bridgestone will see a Bandag plant built in the Caucasus for the first time, with Tegeta becoming the exclusive regional operator. The plant will use Bandag’s cutting-edge tire retreading technology to extend the life of truck and bus tires. Bandag, a Bridgestone subsidiary, produces millions of high-quality retreaded tires annually for reuse in markets around the world.

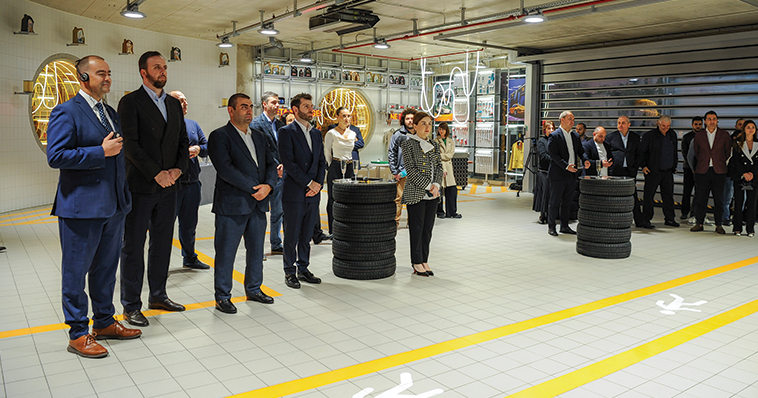

This agreement between Tegeta Motors and Bridgestone was signed in Tbilisi at the company’s multi-functional service center. Representatives from Bridgestone, among them Jacques Fourier, President of Bridgestone Core Tire Business Africa & Middle East, flew into Georgia to attend the event.

Ekaterine Kavtaradze, Chief Executive Officer of Tegeta Holding: “The 27-year partnership between Tegeta Motors and Bridgestone is entering a new phase, and we are delighted to welcome representatives of the global brand on this significant occasion. Our partnership has deepened considerably over the years, and today we serve as the regional distributor of the Japanese brand. As the market has grown and our geographic reach expanded, the need for new strategic developments has become clear. The construction of the Bandag plant reflects a long-term vision shared by both companies, grounded in our mutual commitment to sustainable development and innovation.

At the initial stage, we aim to produce up to 5,000 tires per year in the region, which will double over the next five years. This will significantly reduce the environmental impact and at the same time lower the costs for our corporate customers.”

$2 million has been invested in the project thus far. At the initial stage, Tegeta Motors will be retreading tires for all types of trucks and buses, doing so in full compliance with international standards, ensuring the full functionality and “like-new” quality of each tire.

At the next stage, the holding plans to export retreaded tires for use in Armenia and Azerbaijan. The casing of a used tire is reinforced with the same high-quality materials applied in new tire manufacturing, yet each retreaded unit costs 30%-40% less than purchasing a new tire. Refurbished tires have a service life of up to 5 years.

Construction of the Bandag plant in Rustavi is scheduled to begin this year, with completion targeted for late 2026. Representatives from Bridgestone and Bandag will oversee the process, ensuring full compliance with global standards. The facility will be outfitted with state-of-the-art Bandag machinery from Europe and the US.

Even before production begins, specialists from the Japanese brand will provide targeted technical training for the Georgian team, followed by six months of on-site supervision once the plant becomes operational.

The facility will operate using Bandag’s standard tire retreading procedure. The process of retreading a tire begins with assessing the integrity of the tire casing using a shearograph—an advanced diagnostic device that detects internal flaws with exceptional precision. The shearograph in Tegeta’s possession is the only one of its kind available in the region, and it will be exclusive to the Rustavi plant. Once structural integrity is confirmed, the remaining tread is replaced with new, high-quality material.

According to Tegeta Motors, the cost per kilometer of a refurbished tire is significantly lower, while still delivering performance comparable to a new tire.

Beyond the financial advantages, the environmental impact is considerable: Bandag’s technology requires less raw material and energy. Extending a tire’s life through multiple cycles reduces waste generation, lowers carbon emissions, and supports more efficient use of natural resources.

Tegeta Motors emphasizes that environmental sustainability and eco-friendly solutions are among its core priorities, and the company continues to expand with a focus on eco-efficient and sustainable production. Future plans include building a tire recycling facility that is fully capable of managing the entire tire life cycle and minimizing waste at every stage.

About Tegeta Motors: Tegeta Motors, part of Tegeta Holding, has operated since 1995, and is one of the leading companies in Georgia’s automotive sector. It provides comprehensive services for cars, minibuses, trucks, buses, and special-purpose equipment. With 28 locations nationwide, the company serves around 500,000 retail customers and 35,000 corporate clients. Tegeta Motors represents over 300 international brands in Georgia, including Bridgestone, Michelin, Varta, Shell, Motul, and Hengst.

S